Gas connections for your oven or dryer are really pretty simple — it’s mostly a matter of screwing stuff together. But knowing FL which fittings to use where can be tricky, and using the wrong ones can lead to a dangerous leak. This article will show you how to safely connect a gas dryer hookup or gas range.

Kits containing a flexible stainless steel gas line and fittings are available at home centers and hardware stores. The kits usually have everything you’ll need, but in some cases, you may have to buy a few more fittings. But before you start, check with your local building inspections department to see if you’re allowed to do your own gas dryer hookup.

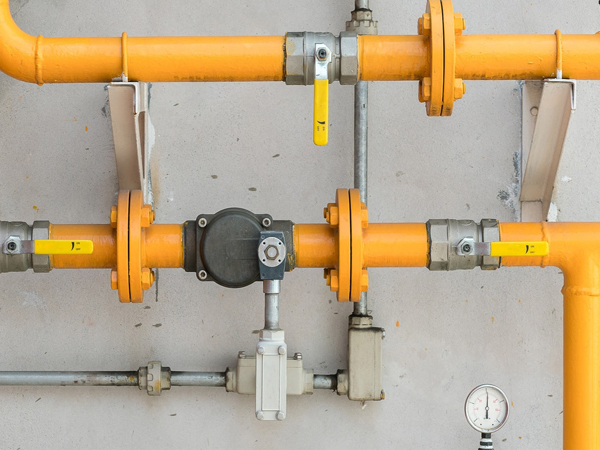

We’ll show you three common gas piping scenarios. We’ll show you one way to make each connection, but there are other equally legitimate ways using common plumbing parts. Don’t be confused by the labels FIP and MIP; they simply stand for female pipe threads and male pipe threads, respectively. And when you buy the parts, don’t hesitate to ask for help. Then screw all the gas line parts together to make sure they fit.

Situation 1: Make Connections to Steel Gas Pipe

If your old appliance is connected with a steel gas pipe and you’re installing a new appliance, buy a gas appliance connecting kit.

Replace the steel gas pipe with the flexible gas supply lines stainless steel tube.

Pro tip: You can’t connect the flare fitting on the flexible gas line supply directly to a steel pipe thread. You have to install the flare fitting that’s included with the kit.

Coat all threaded pipe connections with pipe thread compound before assembly.

If necessary, use a bushing to reduce the existing 3/4-inch female pipe thread to 1/2 inch.

Use a 90-degree elbow at the stove to avoid kinking the gas tubing when you push the stove against the wall.

Before you replace an old valve, find and turn off the main gas valve to the house.

Note: The main gas valve is usually located near where the gas line enters the house.

Connections to Soft Copper

Connections for flexible “soft” copper are made by flaring the end of the soft copper tubing with a special flaring tool and installing flare fittings that have a matching cone-shaped meeting surface. Common sizes of flare fittings are 3/8 inch, 1/2 inch, and 5/8 inch.

Match flare fittings to the outside diameter of the soft copper you’re connecting to.

Note: The photo below shows a soft copper line that’s kinked and should be replaced. There are two options:

Cut a new length of coiled soft copper, flare the ends and connect it with flare fitting.

Or replace the damaged tubing with a flexible stainless connector as shown here.

If the flare fitting on the flexible stainless gas line matches the size of the flare fitting on the existing gas valve, you can simply screw it on.

If the fittings don’t match, one solution is to replace the valve with one that has a flare fitting on one side and a 1/2-inch female pipe thread on the other side.

Use the adapter included with your hookup kit to connect the flexible gas line.